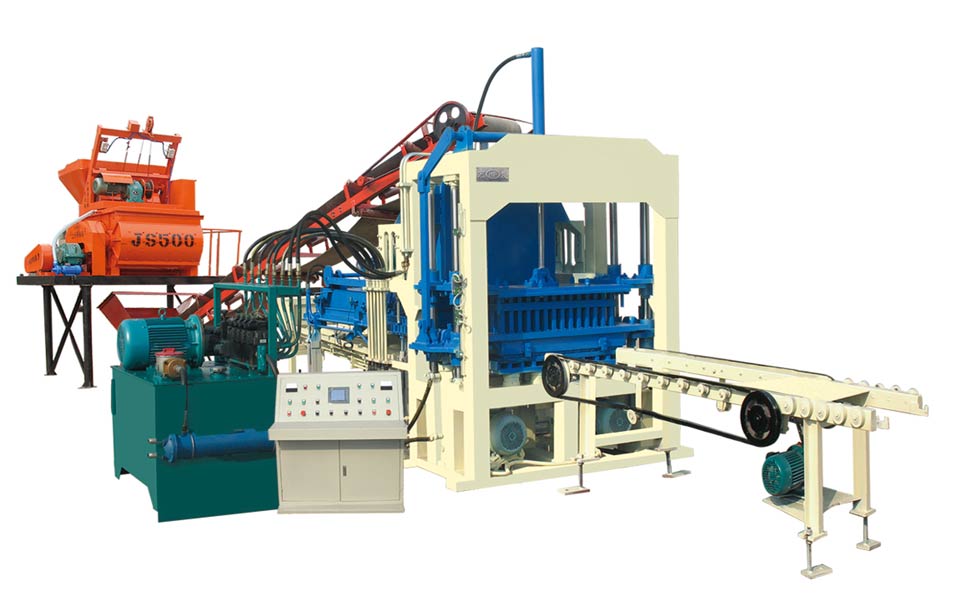

Using the right machines is essential for a successful construction project. One of the most crucial machines used in these projects is a brick-making machine. From manual to fully-automatic, these machines have come a long way to helping the construction industry. They help to produce bricks quickly so that you can maximize your earning potential. Fully-automatic machines cost more compared to manual brick-making machines. But what are the factors that determine the price of these machines? Let’s find out.

1. Faster production time

Fully-automatic brick-making machines produce bricks extremely quickly. This allows you to build your inventory in no time at all. Manual brick-making machines take longer compared to semi-automatic or fully-automatic machines. With a higher production capacity, you will be able to produce more bricks, thus increasing more revenue. It is also helpful in construction projects where you need bricks immediately. Fully-automatic machines can deliver more than 1500 solid bricks in an hour.

2. Consistent results

There is hardly any chance of error in a fully-automatic brick-making machine. This is another factor that increases its overall cost. From mixing ingredients to delivering both solid and hollow blocks, these machines for brick making can perform everything automatically, thus reducing the risks of making an error. Most importantly, every brick that comes out of these machines has the same shape and size. This is the consistency that construction managers demand. Manual brick-making machines may not have the same level of accuracy as these machines.

3. Lower labor expenses

Imagine the amount of money you will save from labor and overhead expenses when you use a fully-automatic brick-making machine. Initially, you may have to spend considerably but these machines help you save over time. You don’t need to hire an expert who will mix the ingredients. The machine specifies the number of ingredients it requires. Once you put everything inside, it will mix the components and start delivering solid or hollow blocks as required.

You also don’t need anyone to count the bricks. All you need to do is specify the number of bricks you need and the machine will delivery accordingly.

4. Round the clock delivery

Human workers require frequent breaks. This means the machine will sit idle for several hours a day. But with a fully-automatic brick-making machine, there’s no question of breaks or letting the machine sit idle. It can produce brick blocks round the clock to meet your demands. Construction companies need thousands of bricks every day. Imagine meeting the demands of multiple companies throughout the month. You will need the machine to work day and night to produce bricks at a swift pace.

But make sure you pay enough attention to the maintenance of these machines. Fully-automatic brick-making machines provide tons of features but they also require high maintenance. However, the cost of maintenance is comparatively less than manual machines. This is another reason why most companies are investing in automatic machines.

These four factors determine the price of brick-making machines in China. It is better to buy a fully-automatic version instead of manual or semi-automatic.