An Introduction to Piling Winches will give you an overview of these tools and their functions. Then, you’ll know what to look for when purchasing one. The two types of winches most commonly used for piling are electric and vibratory. This article will discuss the differences between these two types. You’ll also learn about the use of these winch machines for construction, and the best way to use them in different circumstances.

Piling

The first method of analysis for piles was the use of oscilloscopes to determine the stresses and loads that the piles experience during driving. Its basic concept is simple: the stresses at the pile head are delayed relative to the stress wave impulse at the “foot” or “head” of the pile. The model was developed by Isaacs, who built it based on a mathematical model involving successive transmission and reflection of waves.

Piling winches

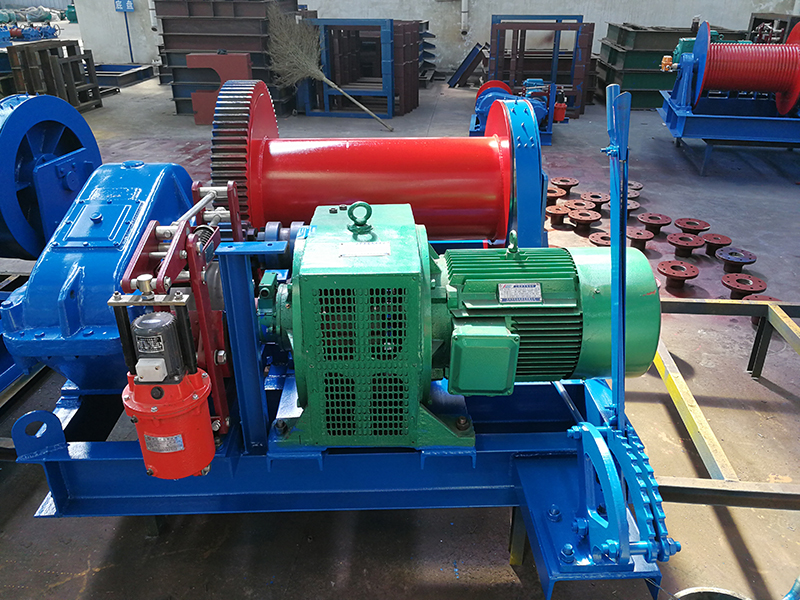

When you’re working with piles, a good way to ensure safe and effective lifting is to use a piling winch machine. These devices are used to lift piles by cable and require special care during installation and use. For the cable to be effective, it should be greased and in an environment free from excess heat or cold. This helps the pile winch maintain its quality and lifespan. To make sure the winch is working properly, it should be inspected periodically to ensure its safety.

Vibratory hammers

The selection of pile driving hammers is critical to the success of the project. The type of pile required will affect the depth of penetration and specifications for water and fine particles. The primary objective is to ensure that the pile can be driven to the required depth. With the advances in technology, piles can now be thicker and wider than ever before. However, the thickness of the sheet head is still a vital consideration when using impact hammers. If the steel section is too thin in relation to the soil density, damage to the sheet head is possible.

Electric winches

Piling winches are used to carry large loads. Some have as much as 1,000 meters of rope, and the larger the drum, the larger the motor and hydraulic system must be. Piling winches can hold anywhere from a few thousand pounds to several hundred tons of load, so they must be built to handle the weight. The operating handle is made of steel and should be in a convenient position for safe and efficient use. For safety reasons, electric winches for sale should be tested before installation to ensure that the motor is in good working order.

Delivery time for piling winches

The delivery time of piling winches depends on the manufacturer and their production facilities. If the goods are already in stock, the delivery time may be as low as 5-10 days. If the goods are not in stock, the delivery time may range from fifteen to thirty days, depending on the quantity of the order. If the order is small, samples are available for purchase but are charged separately. This is a good option if the amount of the purchase is not large.

Calculating fatigue load for piling winches

The calculation of the fatigue load of a piling winch should be carried out according to the pile makeup schedule and for the welds and padeye of the piling. The fatigue load should be calculated using the local stress range derived from wave equation analysis. The location of the girth weld should be determined from the makeup schedule for the piling. The local response should include SCF effect and the number of cycles of stress history per blow should be obtained using variable amplitude counting. To learn more, visit the winch website: https://winchmachines.com/