Choosing a winch suitable for Indonesia requires careful consideration of various factors such as the intended application, environmental conditions, load capacity requirements, power source availability, and budget constraints. Indonesia is a diverse country with a range of industries and terrains, from marine and offshore applications to construction and forestry. In this passage, we will discuss key considerations and steps for choosing a winch that meets the specific needs and challenges in Indonesia.

Define the Application and Requirements

Start by clearly defining the application for which the winch will be used. Identify whether it will be used for marine operations, off-road vehicles, industrial lifting, construction projects, or other purposes. Determine the required load capacity, line speed, duty cycle, and operating environment (e.g., temperature, humidity, saltwater exposure).

Consider Environmental Conditions

Indonesia’s diverse climate and terrain present varying environmental challenges. If the winch will be used in coastal areas or offshore, consider factors such as saltwater corrosion resistance, waterproofing, and marine-grade construction. For inland applications, assess the impact of humidity, dust, heat, and potential exposure to harsh elements on the winch’s performance and durability.

Evaluate Load Capacity and Line Speed

Choose a winch with an appropriate load capacity and line speed that matches the intended application. Consider factors such as the weight of the loads to be lifted or pulled, the distance over which the winch will operate, and the speed at which the operation needs to be completed. Select a winch with a sufficient safety margin to handle unexpected loads or conditions.

Select the Power Source

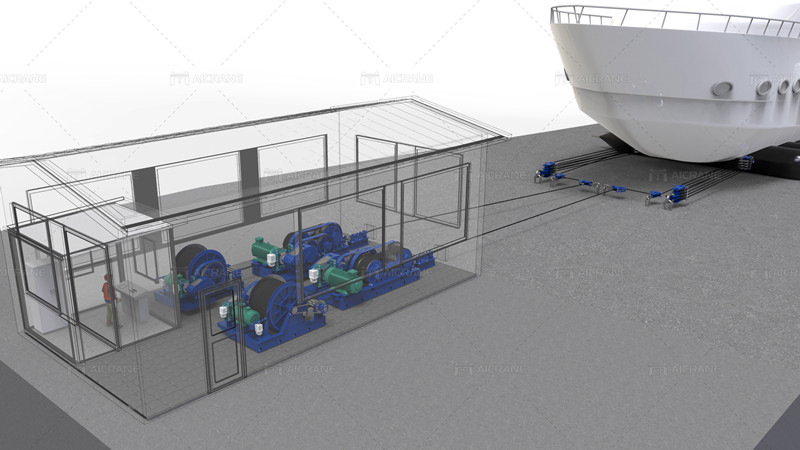

Determine the available power sources for operating the winch. Options may include hydraulic, electric, pneumatic, or manual power. Consider factors such as power availability, efficiency, reliability, and ease of maintenance. Hydraulic winches are often preferred for heavy-duty applications and remote locations, while electric winches offer versatility and ease of use.

Choose the Right Winch Type

Based on the application and power source, choose the appropriate type of winch. Common types include drum winches, capstan winches, planetary gear winches, worm gear winches, and hydraulic winches. Consider factors such as pulling force, line speed, compactness, and compatibility with mounting options (e.g., vehicle-mounted, stationary, portable).

Assess Safety Features and Compliance

Prioritize safety by selecting a winch with essential safety features such as overload protection, emergency stop mechanisms, automatic braking systems, and fail-safe controls. Ensure that the winch complies with relevant safety standards, regulations, and certifications applicable in Indonesia.

Evaluate Durability and Reliability

Choose a winch from reputable winch manufacturers known for quality construction, durability, and reliability. Consider factors such as materials used (e.g., stainless steel, aluminum, high-strength alloys), sealing against environmental elements, corrosion resistance, and warranty coverage. Review customer reviews, testimonials, and industry ratings to assess the winch’s performance and longevity.

Consider Maintenance and Service Support

Evaluate the availability of maintenance services, spare parts, and technical support for the chosen winch model. Choose a winch manufacturer or supplier that offers comprehensive maintenance programs, training for operators and maintenance personnel, and prompt customer support. Consider factors such as ease of servicing, access to spare parts, and warranty terms.

Budget and Cost Considerations

Set a budget for purchasing the winch and consider overall cost-effectiveness over the equipment’s lifecycle. Compare prices from different suppliers, but prioritize value, quality, and long-term reliability over upfront costs alone. Consider factors such as maintenance expenses, operating efficiency, downtime costs, and return on investment (ROI).

Seek Expert Advice and Consultation

When in doubt or facing complex requirements, seek expert advice and consultation from heavy duty winch specialists, engineers, or industry professionals. Discuss your specific needs, challenges, and operating conditions in Indonesia to get tailored recommendations and solutions.

In conclusion, choosing a winch suitable for Indonesia requires a systematic approach that considers application requirements, environmental conditions, load capacity, power source, safety features, durability, maintenance support, budget constraints, and expert advice. By carefully assessing these factors and selecting the right winch model from reputable manufacturers or suppliers, you can ensure optimal performance, reliability, and safety in various industries and applications across Indonesia.