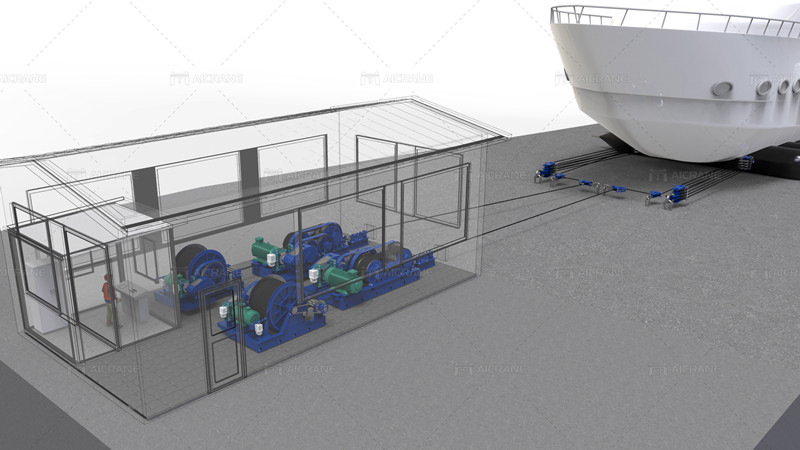

Maintenance plays a crucial role in ensuring the optimal performance, reliability, and longevity of slipway winches with rail trolleys. These specialized systems are commonly used in marine and shipyard operations for launching and retrieving vessels from slipways. Proper maintenance practices not only enhance safety but also reduce downtime, repair costs, and equipment failures. In this passage, we will discuss essential maintenance tips for slipway winches with rail trolleys to maximize their efficiency and lifespan.

Regular Inspection Routine

Implement a regular inspection routine for the slipway winch and rail trolley system. Conduct visual inspections of key components such as cables, ropes, pulleys, sheaves, bearings, gears, brakes, motors, and control panels. Look for signs of wear, corrosion, misalignment, loose connections, leaks, or any abnormal conditions that may indicate potential issues.

Lubrication and Greasing

Ensure proper lubrication of moving parts and components to reduce friction, wear, and corrosion. Use recommended lubricants, greases, and corrosion inhibitors suitable for marine environments. Lubricate cables, chains, gears, bearings, shafts, and sliding surfaces regularly according to manufacturer guidelines and maintenance schedules.

Tension and Alignment Checks

Monitor and maintain proper tension in cables, ropes, and chains to prevent slippage, stretching, or overloading. Check for proper alignment of rails, tracks, wheels, and trolley assemblies to ensure smooth and reliable movement along the slipway. Adjust tension, alignment, and tracking as needed to optimize performance and safety.

Electrical System Inspection

Inspect the electrical system components including wiring, connectors, terminals, switches, relays, fuses, and circuit breakers. Check for signs of overheating, loose connections, insulation damage, or electrical faults that could affect the operation of the winch and rail trolley. Clean electrical contacts and terminals regularly to maintain conductivity and prevent corrosion.

Brake System Maintenance

Maintain and test the brake system regularly to ensure proper functioning and safety during winch operations. Inspect brake pads, discs, calipers, actuators, hydraulic systems, and control mechanisms for wear, leaks, or malfunctions. Adjust brake settings, replace worn components, and test brake performance under load conditions.

Cleaning and Corrosion Prevention

Keep the slipway winch and rail trolley system clean and free of debris, dirt, salt, grease, and other contaminants. Use water-resistant coatings, paints, or protective coatings on exposed metal surfaces to prevent corrosion and rust formation. Clean and rinse equipment after use in saltwater environments to reduce corrosion risks.

Emergency Stop and Safety Systems

Test and calibrate emergency stop systems, safety interlocks, limit switches, and overload protection devices regularly. Ensure that emergency stop buttons, alarms, lights, and warning signals are functional and easily accessible. Train personnel on emergency procedures, evacuation routes, and safety protocols in case of equipment failure or accidents.

Operational Testing and Load Checks

Conduct periodic operational testing and load checks to evaluate the performance and capacity of the slipway winch and rail trolley system. Test functions such as hoisting, lowering, traversing, braking, and emergency stops under controlled conditions. Perform load tests with simulated loads to verify the system’s capacity and safety margins.

Documentation and Record-Keeping

Maintain detailed documentation, maintenance logs, inspection reports, and service records for the slipway marine winch and rail trolley system. Record maintenance activities, repairs, replacements, upgrades, and inspections performed. Keep manufacturer manuals, spare parts lists, technical specifications, and safety guidelines accessible for reference.

Training and Personnel Competency

Provide training and competency assessments for personnel involved in operating, maintaining, and servicing the slipway winch and rail trolley system. Ensure that operators, technicians, and maintenance personnel are familiar with safety procedures, equipment operation, troubleshooting techniques, and emergency response protocols.

By following these maintenance tips and best practices, owners, operators, and maintenance teams can ensure the safe, reliable, and efficient operation of slipway winches with rail trolleys. Regular maintenance, inspections, testing, and training are essential for maximizing equipment performance, minimizing downtime, and enhancing overall operational safety in marine and shipyard environments.