Container gantry cranes, also referred to as container handling gantry cranes or RMG (Rail Mounted Gantry) container cranes, play a vital role in the efficient movement and stacking of shipping containers in ports and container terminals. These towering structures are marvels of engineering, combining strength, precision, and automation to streamline the container handling process. In this article, we will delve into the inner workings of a container gantry crane, shedding light on its mechanisms and highlighting its importance in modern-day logistics.

Structural Design and Components:

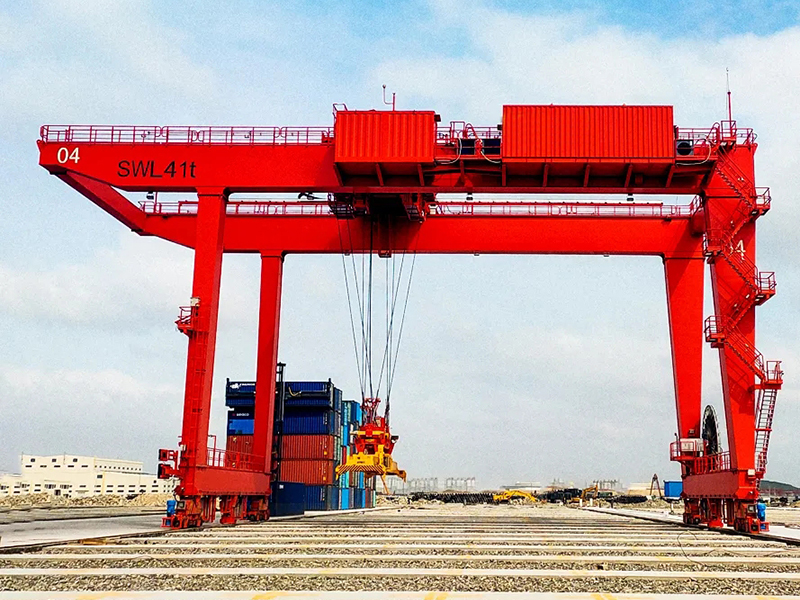

A container gantry crane consists of several key components that work together to facilitate container handling operations. The main structure typically includes supporting legs, a horizontal beam called the boom, and a trolley that traverses along the boom. The trolley is equipped with spreader beams, which securely hold and lift containers during operations. These container handling gantry cranes are usually rail-mounted, allowing them to move along tracks parallel to the terminal’s storage yard.

Lifting Capabilities:

Container gantry cranes are renowned for their impressive lifting capacities. They can handle multiple containers simultaneously, with models ranging from single-lift to double, triple, or even quad-lift configurations. This capability greatly enhances operational efficiency, enabling the simultaneous transfer of containers between ships, trucks, and storage yards.

Automation and Control Systems:

Modern container gantry cranes are often equipped with sophisticated automation and control systems, further optimizing container handling processes. These systems utilize advanced technologies such as GPS, sensors, and cameras to precisely position the crane and ensure accurate container placement. Automated systems also enhance safety by monitoring load limits and preventing overloading.

Power Supply and Operation:

Container gantry cranes require substantial power to operate efficiently. Typically, they are powered by electricity, either through a dedicated power supply or an onboard diesel generator. The power is transmitted to the crane’s motors, which control the various movements of the rail mounted crane, including lifting, lowering, trolley movement, and boom extension.

Safety Measures:

Safety is paramount in container handling operations, and gantry cranes incorporate multiple safety features to protect personnel and cargo. These include load monitoring systems, anti-collision devices, and emergency stop mechanisms. Additionally, regular maintenance and inspections are conducted to ensure the structural integrity and operational reliability of the cranes.

Conclusion:

Container gantry cranes are essential assets in today’s global logistics industry, facilitating the smooth movement and stacking of shipping containers in ports and terminals. Their robust design, impressive lifting capabilities, automation systems, and stringent safety measures make them indispensable in handling large volumes of containers efficiently and effectively. As technology continues to advance, we can expect further enhancements in the functionality and performance of container gantry cranes, ensuring the continued optimization of container handling operations worldwide. For more info, visit https://steelmillcranes.com/