Container gantry cranes play a pivotal role in modern port operations, facilitating the seamless movement of containers from ships to land and vice versa. As ports strive for efficiency and productivity, the decision to invest in a container gantry crane involves a careful consideration of price versus quality. Balancing cost-effectiveness with operational excellence is paramount in this dynamic industry. This passage delves into the intricate relationship between container gantry crane prices and their corresponding quality, exploring the factors that influence this balance and the long-term implications for port operations.

The Importance of Container Gantry Cranes in Port Operations

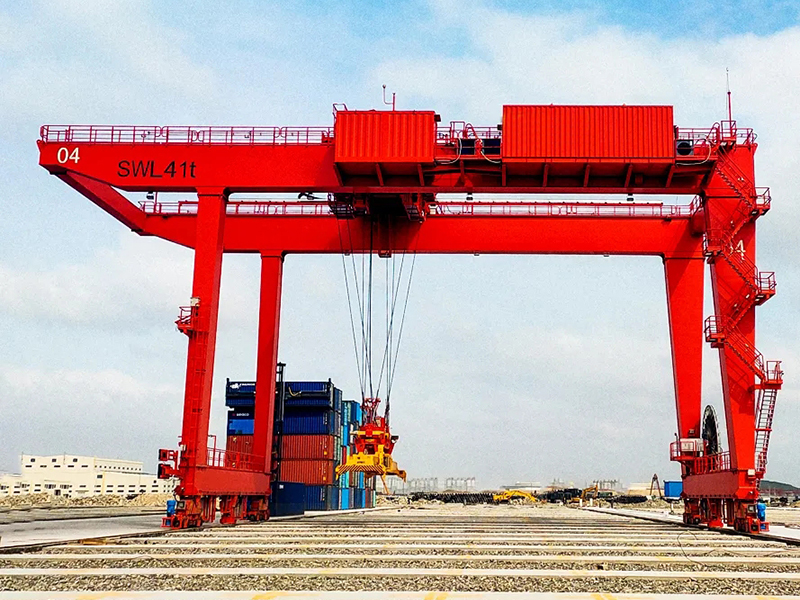

Container gantry cranes are indispensable in the global logistics chain, serving as the backbone of port operations. These towering structures are responsible for lifting and maneuvering shipping containers with precision, ensuring a smooth transfer between vessels and the terminal yard. The efficiency and reliability of these cranes directly impact a port’s throughput capacity, affecting turnaround times, vessel schedules, and overall operational efficiency.

Understanding the Factors Influencing Price

The price of container gantry cranes can vary significantly based on several factors. Key considerations include the crane’s lifting capacity, span, outreach, hoisting speed, and the sophistication of its control systems. Additionally, environmental factors, such as the climate of the port location, may necessitate special features or coatings to protect against corrosion and ensure a longer lifespan. The reputation of the crane manufacturer, warranty terms, and after-sales support also contribute to the overall cost.

Lifting Capacity and Span

One of the primary determinants of a container gantry crane’s price is its lifting capacity. The heavy duty cranes designed to handle larger containers or multiple containers simultaneously come at a higher cost due to the robust engineering required to support heavy loads. Similarly, the span, or the width between the crane’s legs, affects both its stability and price. Wider spans allow for greater flexibility in handling containers across multiple lanes but require more substantial construction, contributing to increased costs.

Outreach and Operational Flexibility

The outreach of a gantry crane refers to its ability to reach containers positioned farther away from the quay. A longer outreach enhances a crane’s operational flexibility, allowing it to handle vessels of varying sizes and configurations. However, extending the outreach typically involves more complex engineering and additional structural components, contributing to a higher price tag. Ports must carefully assess their specific needs and vessel types to determine the optimal outreach for their container gantry crane.

Hoisting Speed and Productivity

The speed at which a container gantry crane can hoist and lower containers significantly influences its overall productivity. Ports with high throughput requirements may prioritize cranes with faster hoisting speeds to minimize vessel turnaround times. While increased hoisting speed can enhance efficiency, it often comes with higher energy consumption and more sophisticated control systems, contributing to an elevated purchase price. Striking the right balance between hoisting speed and energy efficiency is crucial in the cost-quality equation.

Control Systems and Automation

Advancements in automation and control systems have revolutionized container handling operations. Modern gantry cranes often feature sophisticated technologies, such as automated container positioning, anti-sway systems, and remote operation capabilities. While these innovations can improve efficiency and reduce the risk of human error, they also add to the overall cost of the crane. Ports must weigh the benefits of automation against the initial investment and ongoing maintenance costs to determine the most cost-effective solution for their specific operational requirements.

Environmental Considerations

The geographical location of a port and its prevailing climate can significantly impact the durability and longevity of container gantry cranes. Ports in corrosive environments, such as those with high salt content in the air, may require special coatings or materials to protect against rust and deterioration. These additional measures contribute to the overall cost of the crane but are essential for ensuring its reliable performance over the long term. Investing in environmental protection features is an integral part of aligning price with quality and sustainability.

Manufacturer Reputation and After-Sales Support

The reputation of the crane manufacturer plays a crucial role in the price-quality dynamic. Established manufacturers with a track record of delivering reliable and durable equipment may command higher prices, reflecting the perceived value of their products. Additionally, the level of after-sales support, including maintenance services, spare parts availability, and technical assistance, should be factored into the decision-making process. Choosing a reputable manufacturer with a strong commitment to customer satisfaction can mitigate the risk of downtime and unexpected maintenance costs.

In the complex landscape of container gantry crane procurement, finding the right balance between container gantry crane price and quality is essential for the sustained success of port operations. Ports must carefully assess their specific needs, considering factors such as lifting capacity, span, outreach, hoisting speed, control systems, and environmental requirements. While upfront costs are a critical consideration, a long-term perspective that prioritizes operational efficiency, reliability, and sustainability is equally important.

Ultimately, investing in a container gantry crane is an investment in the future of port operations. Ports that prioritize the alignment of price with quality, considering both immediate and long-term factors, are better positioned to enhance their competitiveness in the global logistics landscape. By striking the right balance, ports can ensure the seamless flow of containers, optimize their throughput capacity, and contribute to the overall efficiency of the supply chain.